Screen masks

Screen masks in detail

Screen masks are the base plates used in the screen printing process and are indispensable for manufacturing electronic products such as printed circuit boards and electronic components. A screen mask consists of a frame + mesh + emulsion (or metal), and a high-precision screen mask is used when printing precise patterns on electronic components. Our screen mask technology is also used in familiar products such as smart phones.

Features of Screen Mask Manufacturing

We are equipped to analyze and propose solutions to screen printing issues

We propose the best combination of mesh, emulsion, etc. for the printing specifications required by customers based on our extensive past data. Since we own our printing facilities, we can make the best proposals for your printing needs by leveraging our experience in joint printing experiments and data analysis. If you find yourself facing issues with screen printing, please do not hesitate to contact us.

Offering products with stable delivery and quality

Many of our customers are highly satisfied that our screen masks have very few defects and can be used without impairing their productivity. In terms of delivery speed, our long years of technical expertise and experience enable us to accommodate short delivery times with an efficient production system. Please contact us if you have any special needs around delivery time and quality.

We specialize in high-precision screen mask fabrication

We have abundant experience in high-precision mask manufacturing based on our technological capabilities and expertise cultivated through the production of screen masks for electronic components. Please feel free to contact us about screen masks that require high accuracy.

Lineup

Metal screen masks

NE masks

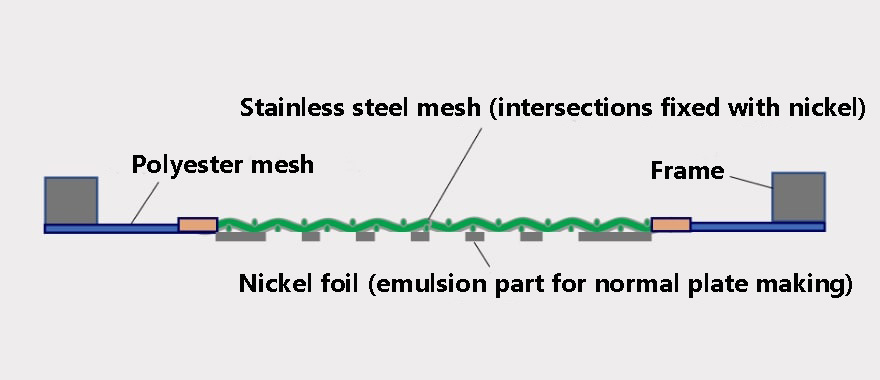

A metal screen mask in which the patterned portion of the screen plate is made of metal foil (nickel) instead of emulsion.

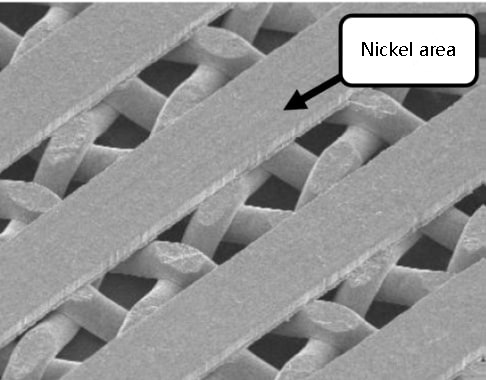

Enlarged view

Structural drawing

Features of NE masks

- ● The initial dimensional accuracy can be maintained because the intersections with the stainless steel mesh are fixed with nickel.

- ●The patterned part is made of metal foil, which provides excellent print and solvent resistance.

- ●Patterned nickel foil is bonded to the mesh, resulting in a highly smooth surface.

Standard mask specifications

| Frame size | ~1000mm×1000mm |

|---|---|

| Mesh | Stainless steel (SUS) mesh (calendered mesh is recommended) |

| Nickel foil dimensions | Approx. 470mm x 570mm (produced according to basic combination specifications) |

| Nickel thickness | 5μm to 100μm (thickness can be discussed separately) |

※Detailed specifications will be confirmed at meeting with the client.

Maintain dimensional accuracy

■Results of plate size method (before and after printing)

After 10,000 shots printing, all 25 measured points maintain dimensions within ±10μm.

※Pitch: 32.5mm, Total pitch: 130mm (see left figure)

Version specifications

450 x 450 frame_NSX430-13CAL_applied plating R2

Printing Conditions

Printing pressure: 0.4MP / GAP: 1.0㎜ / Squeegee speed: 150㎜ sec

※Accuracy depends on mesh strength, tension, target pattern, etc.

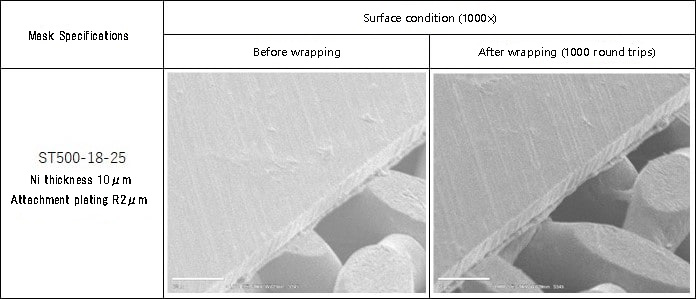

Solvent and print resistance

Edge wear condition (by rubbing test)

Rubbing test on the plate film was performed using a rag impregnated with acetone.

After rubbing test (1000 cycles), there is almost no change at the edges.

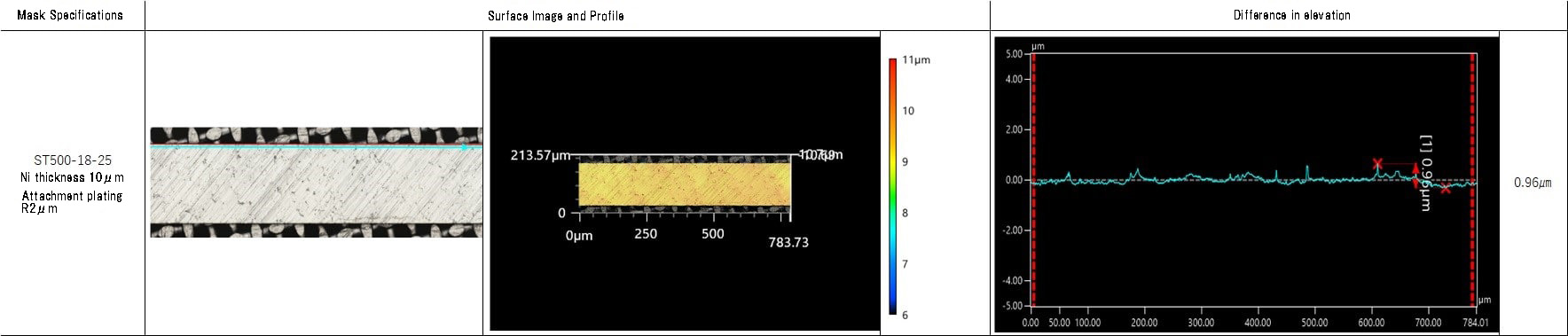

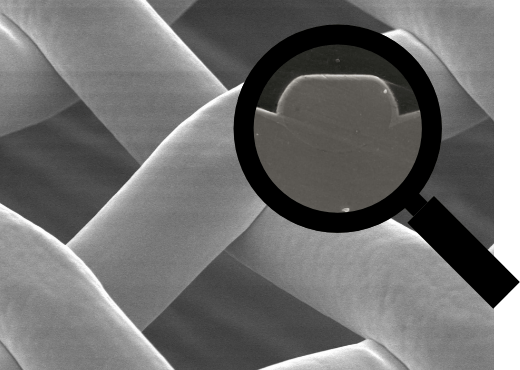

High smoothness

The NE mask has a pattern formed by metal foil (Ni) and has a smooth surface.

Therefore, it is expected to improve the straightness of the printing process.

Edge irregularity measurement

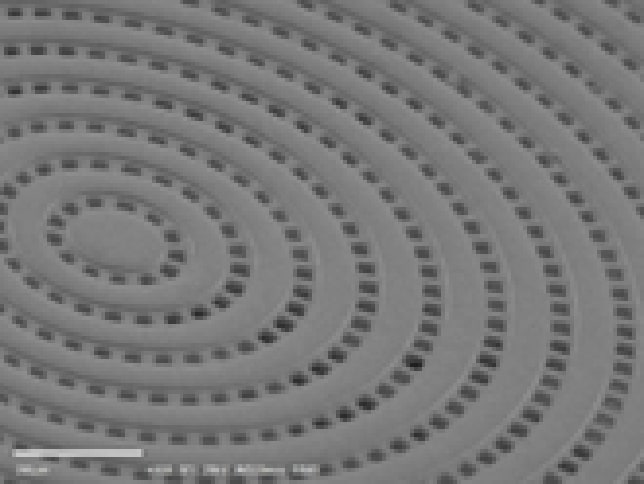

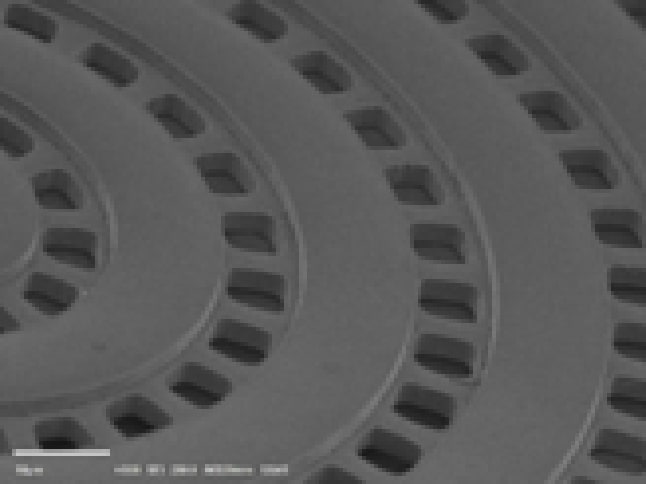

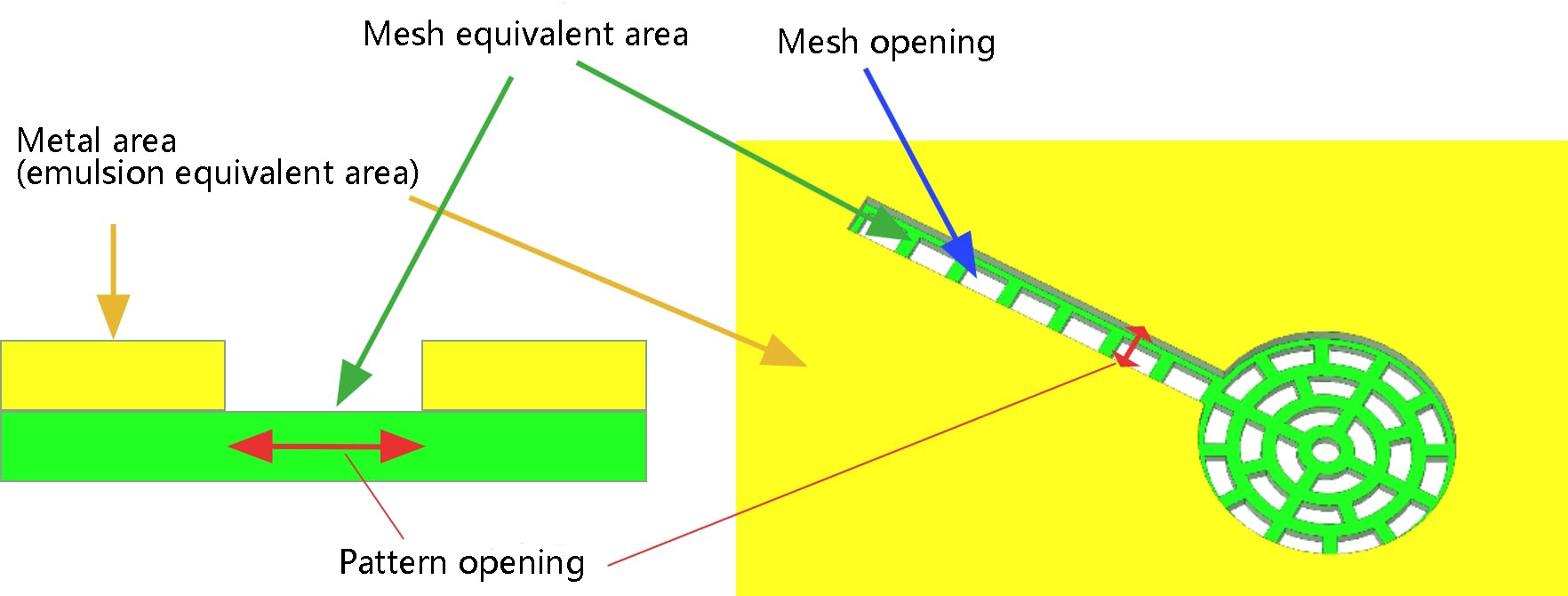

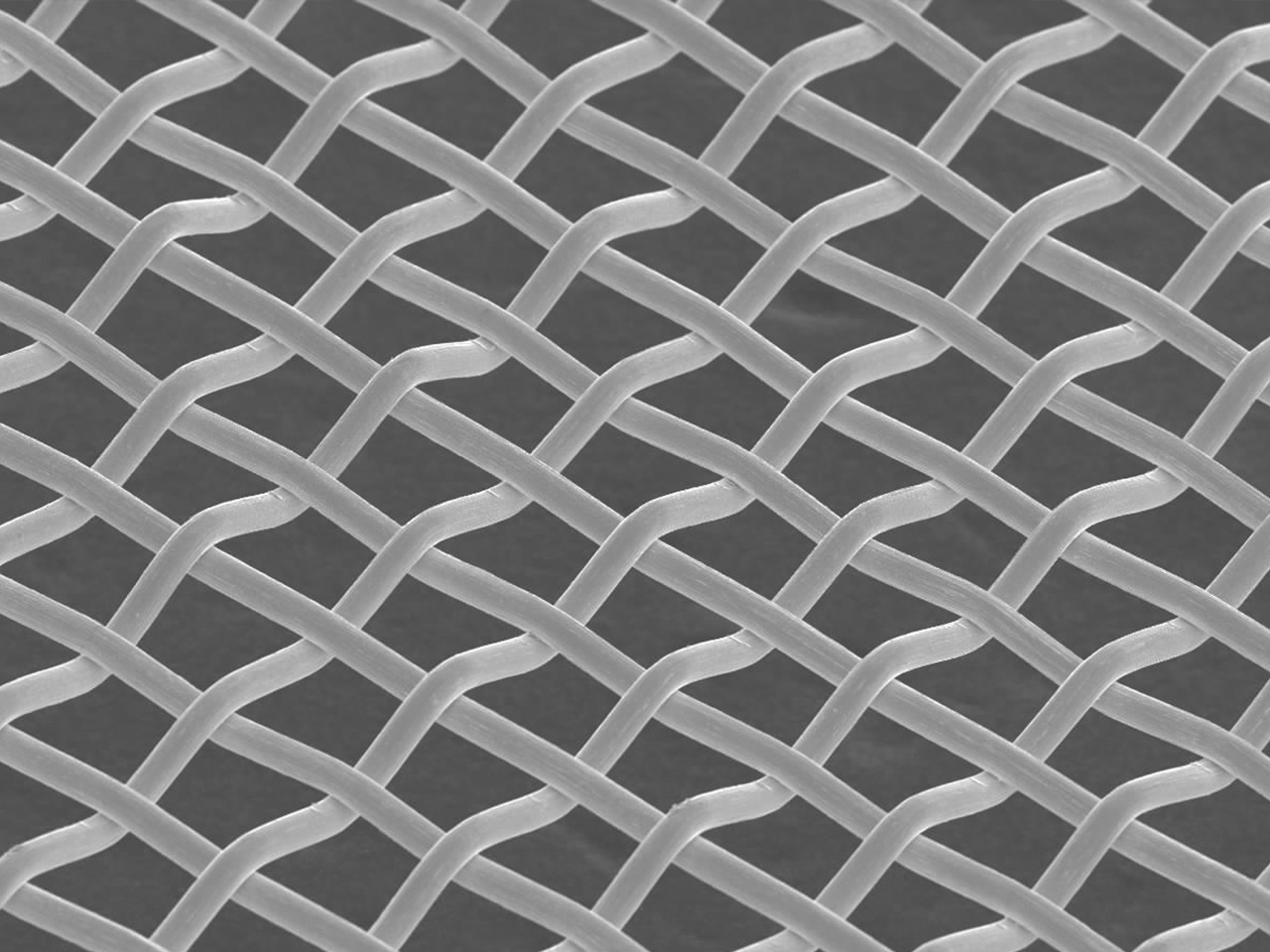

FD masks

This is a new generation of screen masks in which the pattern (emulsion area) and mesh part of the screen mask are fabricated by electroforming.

Since it can be individually designed to take into account overlap or occlusion with the pattern, which cannot be controlled with ordinary woven mesh, it allows for aperture formation more tailored to the pattern in question.

*Patent No. 7108771 (printing mask), Patent No. 7125534 (metal mask for printing), Patent No. 7125533 (method of manufacturing metal masks for printing)

FD mask structure

Example of aperture placement suitable for the pattern

| Woven mesh mask | FD masks | ||

|---|---|---|---|

| Screen masks | Printed matter | Screen masks | Printed matter |

|

|

|

|

| With a woven mesh mask, the aperture and mesh overlap and may not print cleanly in some places, as in the red circled area. | FD masks can be designed such that the aperture and printed pattern overlap uniformly, mitigating the situation described above. | ||

*Please contact us for details regarding specifications.

Emulsion Screen Mask

Mesh

We offer a wide variety of mesh solutions, such as stainless steel, polyester, and plated mesh.

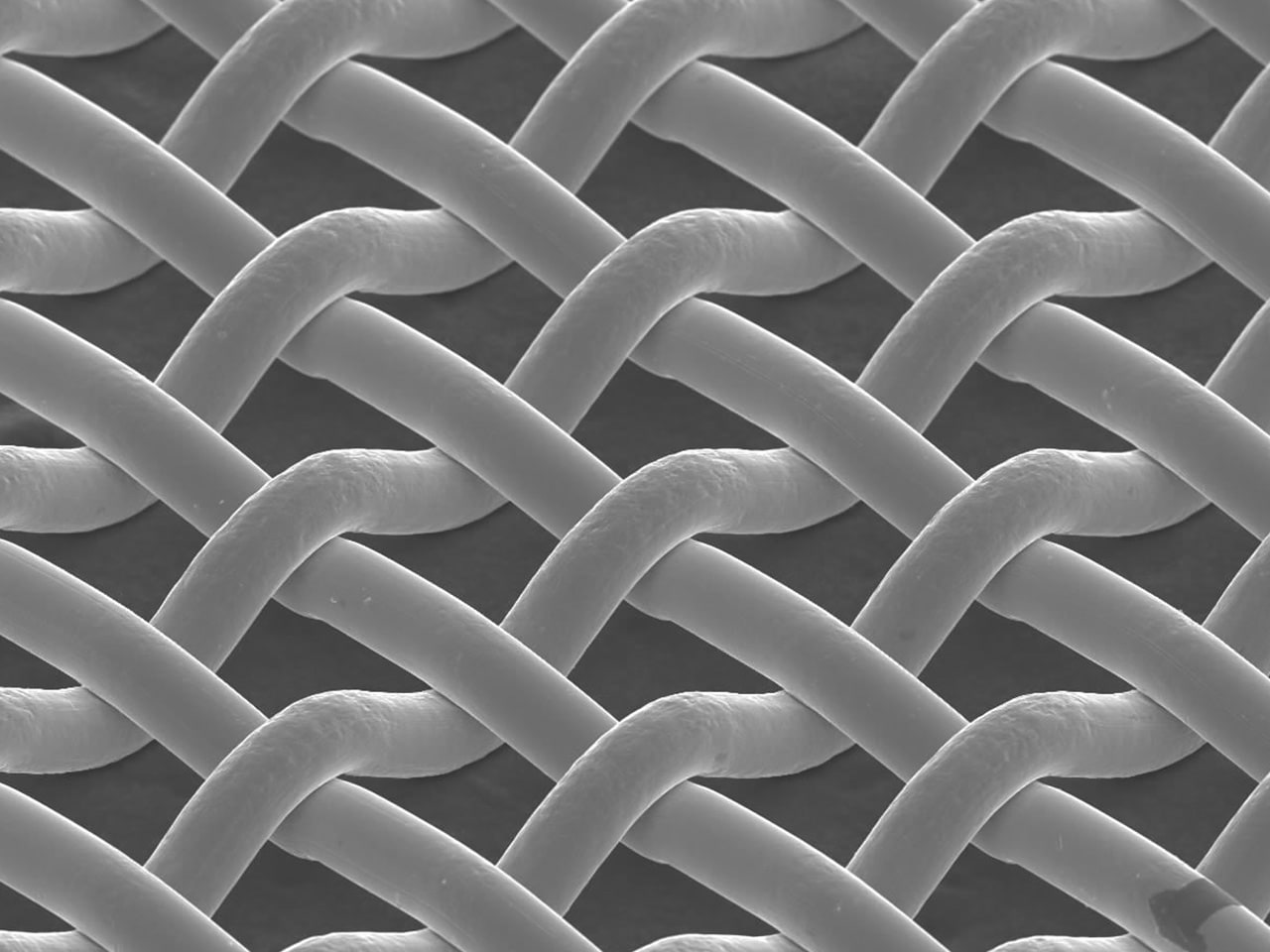

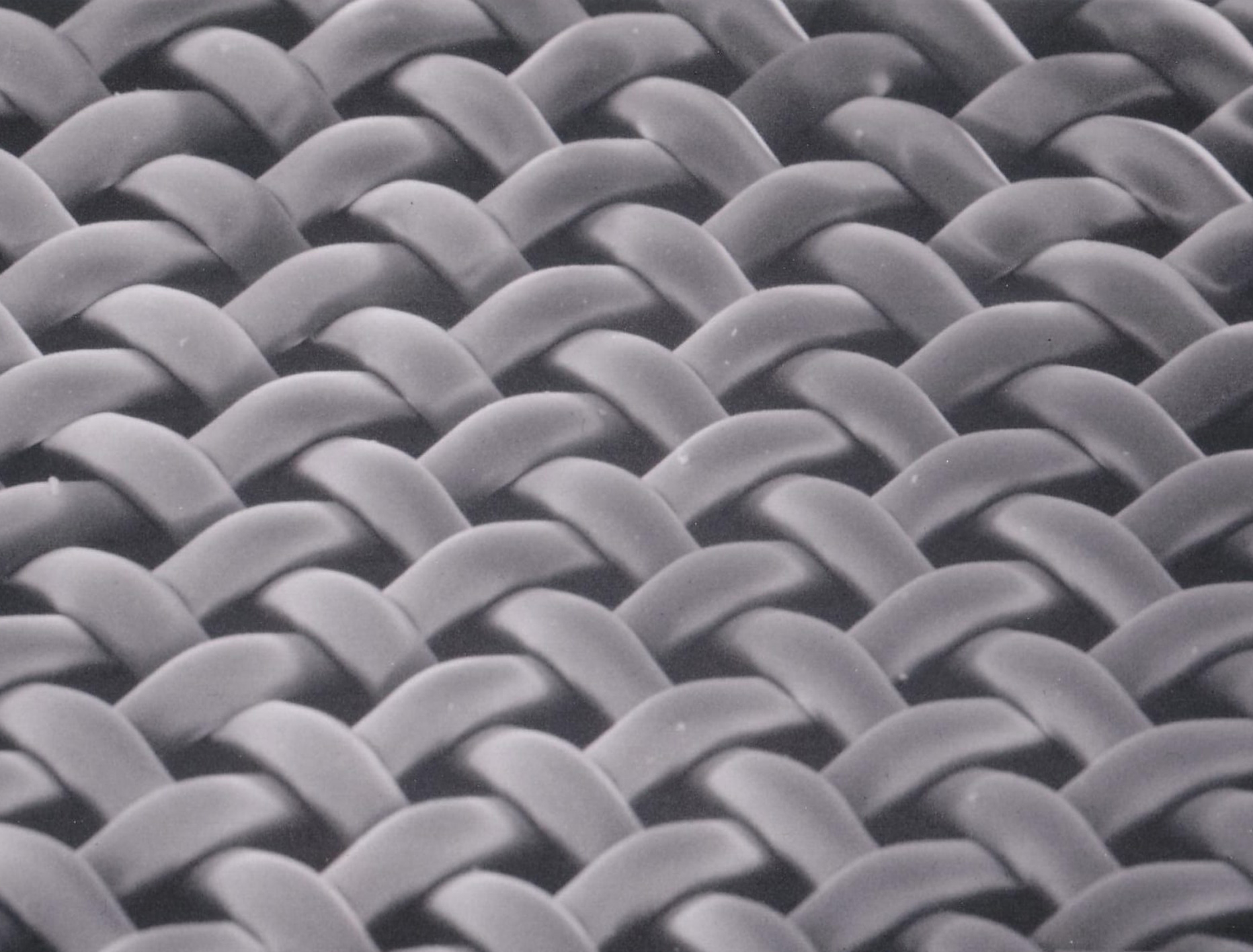

Stainless steel mesh

ST line

- This is a plain weave mesh made of stainless steel wire with excellent printability and a proven track record of performance.

- A wide range of variations are available, from 70 mesh for thick coatings to 900 mesh for fine patterns.

- Discharge volume can be adjusted by calendering.

SX line

- Compared to conventional stainless steel meshes, it has three times the tensile strength and 1/8 the elongation, giving it superior performance.

- This fine-pattern mesh leverages the property of the wires to ensure a high aperture ratio with ultrafine wires.

- Even high-viscosity paste can be easily printed with low printing pressure, enabling patterning with excellent shape accuracy.

- Twill weaving is also available.

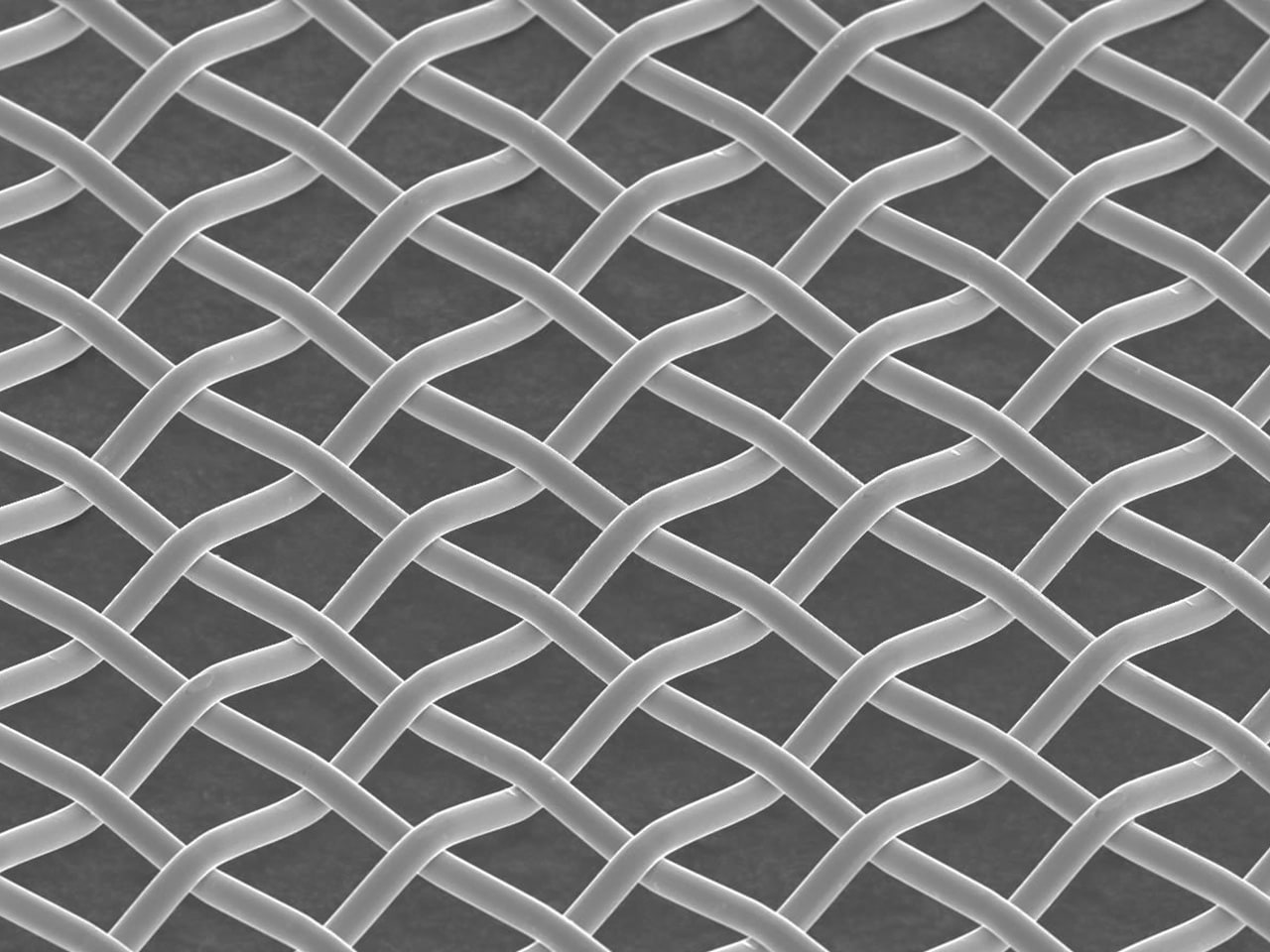

Plated mesh

- By plating the above metal mesh and fixing the intersection points, the elongation is minimized.

- This is effective for printing that requires high dimensional accuracy.

- By controlling the plating thickness, the discharge volume can be more finely adjusted.

Polyester mesh

- This mesh has a high elastic modulus and excellent cost performance, with good adhesion to substrates.

- It is used in a wide range of applications, such as printed circuit boards, flexible circuit boards, and membrane sheets.

Other specialized meshes

- Tungsten mesh

- V screens

- Mesh metal mesh

Emulsions

The following is a summary of the characteristics of different emulsions used in screen masks. Please use this as a reference when selecting an emulsion.

| Product name | Features | Resolution | Smoothness | Solvent resistance | Abrasion resistance | Adhesion |

|---|---|---|---|---|---|---|

| NOA | This is the standard emulsion used by TAKEDA TOPRO. It has excellent resolution, abrasion resistance, and solvent resistance. It also offers excellent durability against polar solvents, and can be used in a wide range of industries. |

|

|

|

|

|

| ARK | This emulsion is based on NOA and exhibits a softer emulsion hardness. It prevents the plate film from cracking due to substrate corner contact. |

|

|

|

|

|

| ARK4 | This emulsion has excellent resolution and high pattern straightness. It is ideal for fine line patterns. |

|

|

|

|

|

| ARK55 | This emulsion has excellent smoothness and abrasion resistance. It inhibits smearing in thin-film printing. |

|

|

|

|

|

| NSL | This is an unpigmented emulsion. It offers excellent resistance to polar solvents and other specific solvents. |

|

|

|

|

|

| PAL | This emulsion was developed for LTCC printing.。 The softness of the plate film prevents paste from penetrating to the reverse side of the plate film, resulting in excellent print resolution. |

|

|

|

|

|

| NCS | This emulsion was developed for MLCC printing. It prevents smearing of MLCC paste. The plate film hardness is soft and durable. |

|

|

|

|

|

| TAP3 | This emulsion was developed for thick-film plate making. |  |

|

|

|

|

| G3 | This is an emulsion developed for printing with water-soluble pastes. Used in combination with a hard film treatment further improves water resistance and prevents emulsion swelling. |

|

|

|

|

|

| T3 | This emulsion can be used for a wide variety of applications, including solid pattern printing. |  |

|

|

|

|

| T4 | It is a multi-performance emulsion that can be used for 100 µm wiring patterns. |  |

|

|

|

|

| T5 | This emulsion has excellent resolution and can be used for fine patterns such as 50um. It also has excellent solvent resistance. |

|

|

|

|

|

Frame

The selection of the plate frame is key to achieving high precision screen printing. We also have a variety of frames other than those in general-purpose sizes.

| General purpose Frame size |

Frame name and dimensions (H x W x t) | |||||||

|---|---|---|---|---|---|---|---|---|

| Casting | Pipe material/strength: weak to strong | |||||||

| B material | C material | SPC4 | I material | SPCK | SPHK | SPK | ||

| – | 20×30×1.5 | 30×40×2.0 | 30×40×3.0 | 30×50×2.74 | 30×42×5.0 (4.0) |

30×60×4.0 (3.0) |

40×80×3.0 | |

| 320×320 | ○ | ○ | ||||||

| 380×380 | ○ | ○ | ||||||

| 450×450 | ○ | ○ | ||||||

| 550×550 | ○ | ○ | ○ | ○ | ||||

| 550×650 | ○ | ○ | ○ | ○ | ||||

| 650×750 | ○ | ○ | ○ | ○ | ○ | |||

| 750×750 | ○ | ○ | ○ | ○ | ○ | |||

| 800×800 | ○ | ○ | ○ | ○ | ○ | |||

| 950×950 | ○ | ○ | ○ | ○ | ○ | |||

| 1000~ | ○ | ○ | ○ | ○ | ||||

We can manufacture various types of masks starting from a single sheet.

Are you looking to have a single prototype piece made? We are equipped to flexibly accommodate small lot orders and other requests. Please do not hesitate to contact us.