Service

Services

Robust, courteous, and prompt customer service system

We offer a full response to customer requests and inquiries at all times.

Service

Rapid response

Delivery

Flexible and

rapid turnaround time

Support

Integrated system from CAD design to mask manufacturing

Quality

Quality control system

Service

Rapid response

TAKEDA TOPRO has established a system in which a sales representative and an administrative representative are assigned as the point of contact for customer service. If a sales representative is out of the office, we can still respond with alacrity by coordinating with the administrative representative to provide express service or respond to urgent problems. We have many solutions and a proven track record of achievements around different issues and consultations clients seek, such as quality improvement, cost reduction, and delivery time reduction of processes using mask products, particularly those for screen printing and photolithography technology. We can offer the best solutions for your issues based on our extensive expertise.

Delivery

Flexible delivery schedule

1. We operate some of our factories during nighttime hours to flexibly respond to customers’ requests for express delivery. We also offer in-person delivery to customers near our plants.

2.With five manufacturing bases in Japan and overseas, we are able to deliver products not only to Asia but also to the world more quickly than other companies based in the Kanto area. (Not only Haneda and Narita, but also Komatsu Airport and Central Japan International Airport are available.)

We can deliver products on the same day at the earliest. (We can also use Komatsu Airport and Chubu International Airport in addition to Haneda and Narita Airport.

Support

Integrated system from CAD design to mask manufacturing

TAKEDA TOPRO supports customers in prototyping and development of masks that meet their required specifications.

We conduct tests on the customer’s products and perform analysis and evaluation using our measuring instruments and other modalities according to the specifications required by the customer; these could be parameters like dimensions, thickness, durability, etc. Our support includes suggestions for improvement based on the results obtained from measurement and evaluation, so you can leave your work to us with peace of mind.

TAKEDA TOPRO’s prototyping is available not only for masks, but also for the entire process spanning from printing machine + paste + mask (plate), allowing you to optimize the entire process.

Support operations for customers’ product manufacturing

CAD design

Generally speaking, we ask our customers to supply us with data for mask fabrication, but we often modify and edit that data according to the customer’s fabrication requirements. In some cases, we design from scratch.

Product development and design stage

We provide strong support from the product development and prototyping stages with our wealth of knowledge, experience, and various analytical data

Mass production stage

During mass production, we offer products with quick delivery and stable quality in order to provide support that leaves our clients highly satisfied with our problem-solving and technical capabilities when it comes to products with outstanding issues.

Workflow up to implementation

Quality

Quality control system

Total pitch measurement system

Basic approach to quality

TAKEDA TOPRO maintains a quality assurance system based on IS09001 and takes all possible measures for quality control. Furthermore, we are committed to contributing to the growth of our customers through continuous improvement in quality and by providing products that are always reliable.

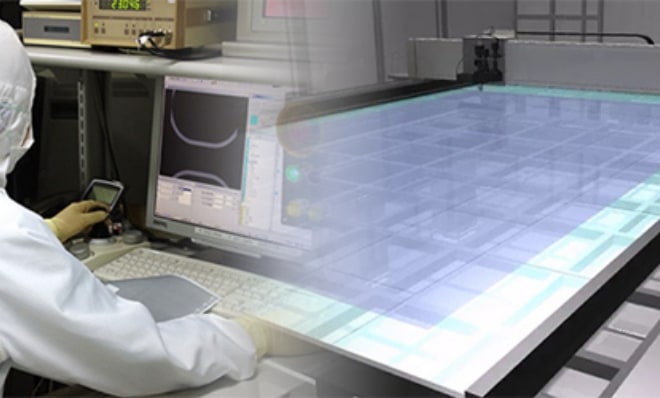

Ultra-precision automatic 2D coordinate measuring device

We perform dimensional measurement and inspection with sub-micron accuracy. We provide stable quality products through quality improvement and quality assurance by utilizing every possible technology to realize high precision measurement, such as stages and clean chambers.

Automatic optical visual inspection system(Auto Optical Inspection System)

Using our proprietary optical technology, image processing capabilities, and inspection algorithms, we can reliably detect extremely minute defects in photomasks with high speed and accuracy.

We can manufacture various types of masks starting from a single sheet.

Are you looking to have a single prototype piece made? We are equipped to flexibly accommodate small lot orders and other requests. Please do not hesitate to contact us.